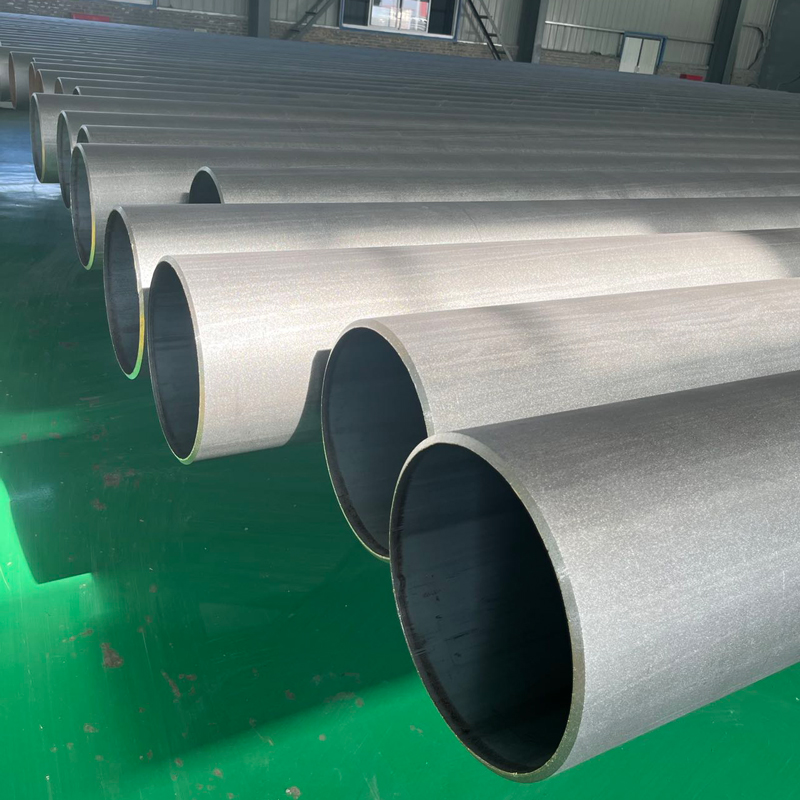

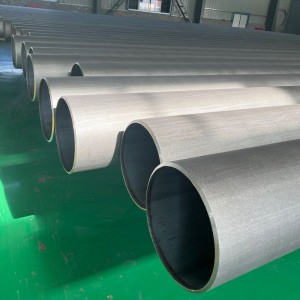

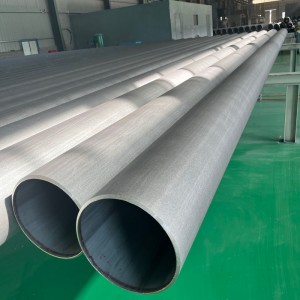

Zophimba za Epoxy Zolumikizidwa ndi Fusion Awwa C213 Standard

Kapangidwe ka zinthu za ufa wa epoxy

Mphamvu yokoka pa 23℃: osachepera 1.2 ndipo pazipita 1.8

Kusanthula kwa sieve: pazipita 2.0

Nthawi ya gel pa 200 ℃: zosakwana 120s

Kuyeretsa ndi kuphulika kwa abrasion

Malo opanda chitsulo ayenera kutsukidwa ndi kuphulika motsatira SSPC-SP10/NACE No. 2 pokhapokha ngati wogula wanena mwanjira ina. Kapangidwe kake ka chivundikiro cha kuphulika kapena kuya kwa mbiri yake kuyenera kukhala 1.5 mil mpaka 4.0 mil (38 µm mpaka 102 µm) motsatira ASTM D4417.

Kutentha

Chitoliro chomwe chatsukidwa chiyenera kutenthedwa kutentha kosakwana 260℃, gwero la kutentha siliyenera kuipitsa pamwamba pa chitoliro.

Kukhuthala

Ufa wophimbawo uyenera kupakidwa pa chitoliro chotenthetsera moto pa makulidwe ofanana a filimu yoyeretsera yosachepera 12 mils (305μm) kunja kapena mkati. Kukhuthala kwakukulu sikuyenera kupitirira 16 mils (406μm) pokhapokha ngati wopanga kapena wogula wapereka malangizo.

Kuyesa magwiridwe antchito a epoxy mwanjira ina

Wogula akhoza kusankha mayeso ena kuti atsimikizire momwe epoxy imagwirira ntchito. Njira zotsatirazi zoyesera, zomwe zonse ziyenera kuchitika pa mphete zoyesera mapaipi opangira, zitha kufotokozedwa:

1. Kubowola kwa ming'alu.

2. Kupindika kwa mawonekedwe.

3. Kusanthula kutentha (DSC).

4. Kupsinjika kosatha (kupindika).

5. Kunyowetsa madzi.

6. Mphamvu.

7. Kuyesa kwa kusweka kwa Cathodic.